Modern TechnologY

Apart from high productivity and precision, STOOSS FORGEMASTER’s prime concern is fast production, individually tailored to customer’s needs, so that the smallest series – as also the industrial-scale production – can be manufactured economically. Many years of experience enabled us to develop processes – some controlled electronically, some manually – which guarantee precision and accuracy from the first to the final step. The annual forging capacity is approximately twenty thousand tons.

Stooss USA‘s goal would be to maintain a stock of material based on your estimated annual usagaes of repetative items. Our stocking program works well with a consistent inventory of product which decreases delivery times to 1–5 business days.

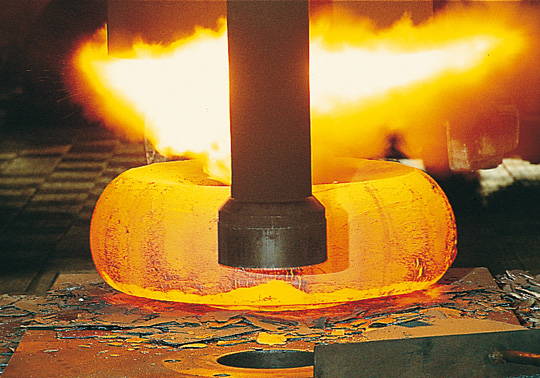

ring mills

The production of seamless hot rolled and profiled rings weighing up to approx. 5 tons are typical STOOSS specialities. In the production of rings, the billets are preformed, punched and then rolled to the required dimensions on ring rolling mills.

open-die forging

STOOSS is extraordinarily competent

also for heavy individual items or small quantities of large parts. Our open-die forging facility produces parts for turbines, gears, valves or machines from 100 kg up to 5 tons.

hammer-forging

Individually forged parts are no problem at our hammer forging facility.

With extraordinary skill, we forge bars, shafts and rings which regularly weigh 30 to 60 kilograms.