News & Chronicle

Review and outlook regarding our milestones and sales activities.

NEWS

2023

November:

FMB, Bad Salzuflen, Germany

May:

Offshore Technology Conference (OTC, Houston)

April:

HANNOVER Exhibition

March:

INNOTEQ, Berne, Switzerland

February:

POWERGEN International, Orlando

2022

June:

CastForge, Stuttgart, Germany

May:

Offshore Technology Conference (OTC, Houston)

POWERGEN, Dallas

2021

November:

SWISS PRODUCTION FORUM, Zurich Oerlikon, Switzerland

FMB, Bad Salzuflen, Germany

September:

ITM Industry (Poznan, Poland)

August:

Offshore Technology Conference (OTC, Houston)

2019

November:

POWERGEN Exhibition, New Orleans

October:

AIRTEC Exhibition, Munich

September:

WEFTEC Exhibition, Chicago

May:

SWISSTECH Exhibition, Basel

Offshore Technology Conference (OTC, Houston)

April:

HANNOVER Exhibition

2018

April:

Offshore Technology Conference (OTC, Houston)

2017

September:

Transfer of STOOSS GMBH from Wetter to Hagen

August:

Conversion of forging furnaces from propane to natural gas

2016

November:

SWISSTECH Exhibition, Basel

April:

HANNOVER Exhibition

2015

November:

MIDEST FAIR, Paris

June:

ACHEMA FAIR, Frankfurt

April:

HANNOVER FAIR

2013

August:

Modernization of 2‘500 t press

April:

HANNOVER FAIR

2012

November:

SWISSTECH Exhibition, Basel

July:

Commissioning of Building No. 9 – Finish machining

2011

Commissioning of the new ring rolling mill

2010

November:

Participation at the SWISSTECH Fair in Basel

2009

April:

HANNOVER FAIR

SQS repeat audit has successfully

been passed

Expansion of the machine shop by 3 new vertical turning lathes

January/February:

Modernisation and upgrade of big ring rolling mill

2008

October:

Expansion of the heat treatment department by 3 new furnaces as well as a new Polymer tank

August:

Opening of machine shop at STOOSS GMBH, Germany

May:

New production hall for the cutting department

2007

September:

STOOSS USA moves into a new office and warehouse

April:

Participation at the HANNOVER FAIR

2005

December:

100-years‘ STOOSS anniversary

August:

Transfer of the Zurich plant into new production buildings in Hedingen

April:

HANNOVER FAIR

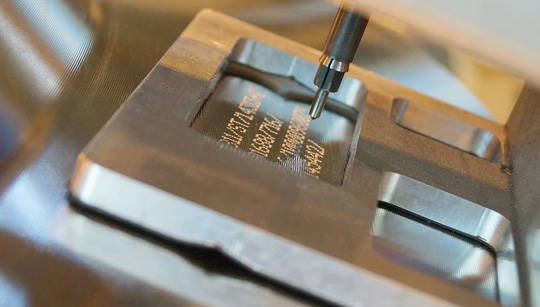

Safety and long product life

Forged parts from STOOSS are outstanding because of their:

material selected on the strength of its analysis and degree of purity

exact shaping

ideal degree of forming

optimum grain structure

minimum allowances, narrow tolerances

thermal treatment relevant to the application

Moreover, they offer exceptional advantages:

excellent manufacture in respect of surface quality and accuracy of form

suitable for processing on CNC

machines

reduction of mechanical processing time, thus saving costs

high degree of security against fatigue cracks