subsidiary us conroe

In Houston, Texas, STOOSS USA Inc. provides North American customers with inventory management as well as pre-machined and finish-machined forging parts.

machining

equipment (usa)

1 Puma 480 CNC Lathe, Max OD Turning 25”, Max Turning length 74”

1 Puma 400 CNC Lathe, Max OD Turning 19”, Max Turning length 40”

2 Doosan 4100 CNC Lathe, Max OD Turning – 19”, Max Turning Length – 35”

1 Mazak Nexus 900 Vertical Lathe-Live Tooling, Max OD Turning 39”,

Max Turning Length 32”

1 Chevaliar Vertical Lathe-Live Tooling, Max OD Turning – 60”,

Max OD Length – 52”

Haass VF-8 Mill, Table Dimensions 36” x 64”, Max Milling Height 30”,

4th axis machining capable

1 Sunfirm CNC Lathe, Max OD Turning – 33”, Max Turning Length – 150”

1 DMTG Manual Lathe, Max OD Turning 18”, Max Turning Length 100”

1 Birmingham Manual Lathe, Max OD Turning 7”, Max OD Turning Length 60”

PRODUCTION FACILITIES (PLANT HEDINGEN)

A 2‘700-ton forging press and a powerful ring rolling mill, both electronically controlled, are the focus of resourceefficient production today. The latest heat treatment equipment and CNC processing machines complete the company‘s state-of-the-art plant.

sawing equipment

10 Band saws in different sizes, saw diameter up to 1’000 mm

forging furnaces

5 Batch furnaces, gas heated

1 Batch furnace, electrically heated

2 Rotating hearth furnace, gas heated

1 Bogie hearth furnace, gas heated

Equipped with temperature control, calibrated thermocouples

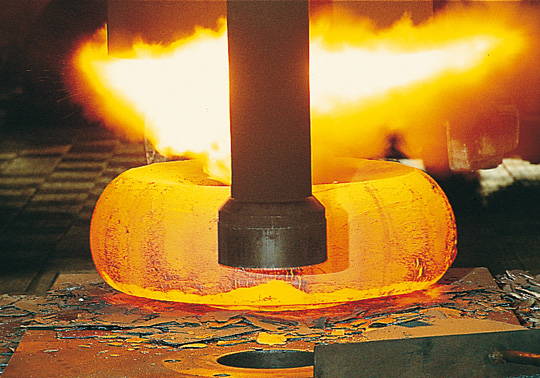

forging facilities

2 Hammers with pile hammer weights 500 + 750 kg

3 Hydraulic forging presses, 1‘200, 1‘600 and 2’700 tons

3 Ring mills up to 3‘500 mm OD and unit weights 5 tons

heat treatment furnaces

4 Electrically heated bogie hearth furnaces (3x 1’000°C, 1x 1’200°C) up to 1’200°C and 2 – 10 tons weight capacity, with fully automatic temperature control and recorder

7 Gaz-heated bogie hearth furnaces (2x 1’180°C, 1x 1’100°C, 4x 1’050°C) and 10 – 30 tons weight capacity, with fully automatic temperature control and recorder

2 Quenching tanks 42 m3 for oil and 52 m3 forwater quenching, equipped with recirculation and cooling system

1 Quenching tank 89 m3, Polymer with recirculation and cooling system

1 Electrically laboratory furnace

testing facilities

Mechanical Tests

1 Tensile test machine

1 Impact test machine*

2 Hardness test machines

*Equipment for low temp. impact tests

NDT Equipment

Ultrasonic testing

Magnetic powder testing

Dey penetrant testing

Visual testing

Laboratory

Macroetch and microetch tests

Corrosion tests

Spectroscopical identity test

Ferrit scope

Dimension control

3D measuring machine

3D electrically measuring arm FARO

machining

equipment (CH)

1 Conventional lathe with horizontal face plates, max. Ø 2’550 x 1‘700 mm

1 Conventional pivot lathe, max. Ø 1’000 x 3’000 mm

8 CNC lathes with horizontal face plate, max. Ø 3’200 x 1‘200 mm

6 CNC pivot lathes, max. Ø 700 x 6’000 mm

1 Drilling machine, max. Ø 130 x 800 mm

1 CNC horizontal boring machine, 3‘000 x 2‘000 x 1‘400 mm

1 CNC milling machine, 1‘525 x 760 x 625 mm

1 CNC machining center 2‘000 x 810 x 630 mm, with NC-divider

1 Shot blasting equipment